Market Dynamics in the Electronic Parts Supplier Arena

What Challenges Do Electronic Parts Supplier Texas Companies Face?

The Power of Customization in Supply Chain Solutions

How to Choose the Right Electronic Parts Supplier?

The Future of Electronic Parts Supply in Texas

What Qualifies as an Electronic Parts Supplier Texas Emergency?

What makes Texas a unique environment for electronic parts suppliers like Synergy Components?

Texas is a vibrant tech hub, offering a compelling mix of innovation and industry strength. As a home to various sectors such as aerospace and consumer electronics, the demand for electronic parts here is consistently high. The state offers excellent infrastructure and a business-friendly climate, fostering symbiotic relationships between suppliers and clients. For Synergy Components, being in Texas means tapping into this dynamic market and adapting swiftly to its shifts and demands.

How does Synergy Components navigate the challenges of a complex supply chain?

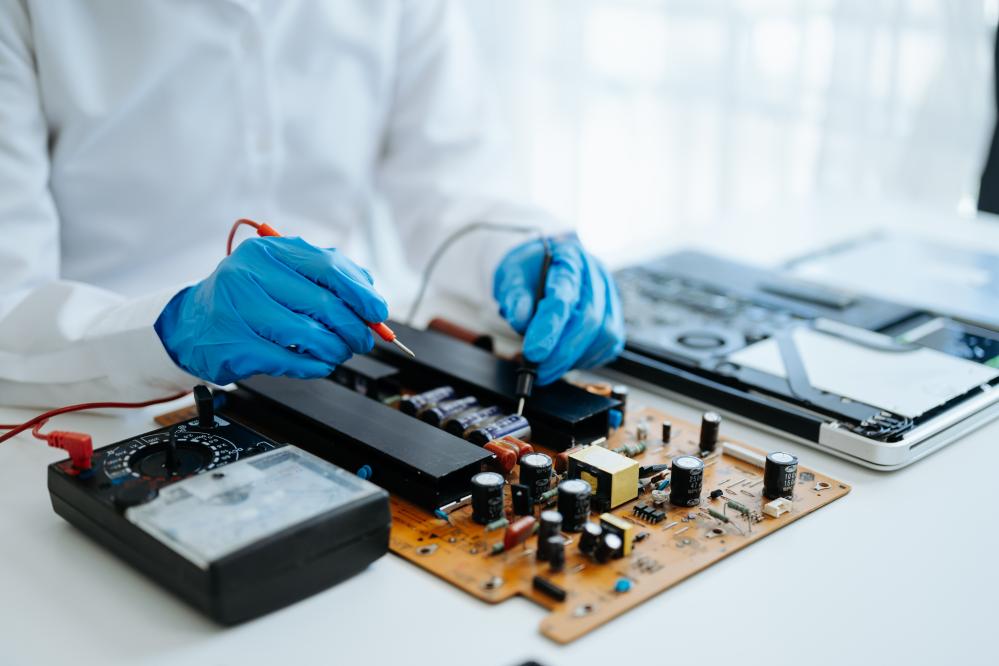

Navigating a complex supply chain requires meticulous planning and robust infrastructure. At Synergy Components, we utilize a vast network of over 5,000 manufacturers and distributors to ensure timely delivery while maintaining quality. Counterfeit components pose a significant risk, so we prioritize avoiding them through rigorous Counterfeit Avoidance & Reliability Testing. Our approach allows us to tackle these challenges head-on, setting a standard for reliability.

Why is customization crucial in supply chain solutions, and how does Synergy Components deliver it?

Customization is essential for managing unique client needs, from rapid prototyping to niche market demands. At Synergy Components, our custom-made solutions go beyond mere product offerings. We tailor inventory and excess material management strategies to maximize efficiency and align with clients’ strategic goals. This personalized approach fosters loyalty and long-term partnerships, crucial in the competitive supply chain industry.

What criteria should companies consider when choosing an electronic parts supplier like Synergy Components?

When selecting a supplier, consider industry certifications like ISO and ESD, which reflect adherence to quality standards. Assess the supplier’s customization capabilities and their network reach for sourcing hard-to-find parts. Client testimonials can also provide real-world insights into a supplier’s reliability. At Synergy Components, our reputation for delivering tailored solutions and maintaining a vast network helps companies align with their long-term strategic goals.

What does the future hold for the electronic parts supply industry in Texas, particularly for companies like Synergy Components?

The future is ripe with opportunities driven by emerging technologies like IoT and AI, boosting demand for specialized components. At Synergy Components, we’re committed to innovation and sustainability, incorporating environmentally conscious practices into our supply chain strategies. Collaborative efforts within Texas’s bustling business ecosystems will further drive the industry forward, allowing us to remain competitive globally.

How does Synergy Components handle emergencies such as supply chain disruptions?

Handling emergencies requires a proactive approach. At Synergy Components, we maintain a responsive communication plan and keep a buffer stock of critical components. We develop supplier redundancies and leverage advanced analytics to foresee potential disruptions. These strategies ensure that we can navigate emergencies effectively, maintaining our clients’ trust and minimizing business impact.

Can you share some examples of client success stories that illustrate Synergy Components’ impact?

One example is Elise A., whose firm was able to recover assets on obsolete semiconductors with our help, thus avoiding counterfeit purchases. Another is Ben M., who appreciated the custom-made power supplies that reduced lead times and overhead costs. Rin Y. was grateful for our assistance during the challenging times post the TÅhoku earthquake and tsunami in 2011. These stories highlight our commitment to providing innovative, customized solutions that meet our clients’ needs effectively.

Resources

- Texas.gov – The official website of the state of Texas, providing information on government services and resources.

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory federal agency within the U.S. Department of Commerce, promoting innovation and industrial competitiveness.

- National Association of Electrical Distributors (NAED) – NAED is a trusted resource for education, networking, and advocacy in the electrical distribution industry.

- Electronics Tutorials – A comprehensive resource for electronics education, tutorials, and practical design guides.

- U.S. Environmental Protection Agency (EPA) – The EPA website provides information on environmental regulations, sustainability practices, and resources for businesses.

Austin

TX

78734