The Importance of Supply Chain Diversification

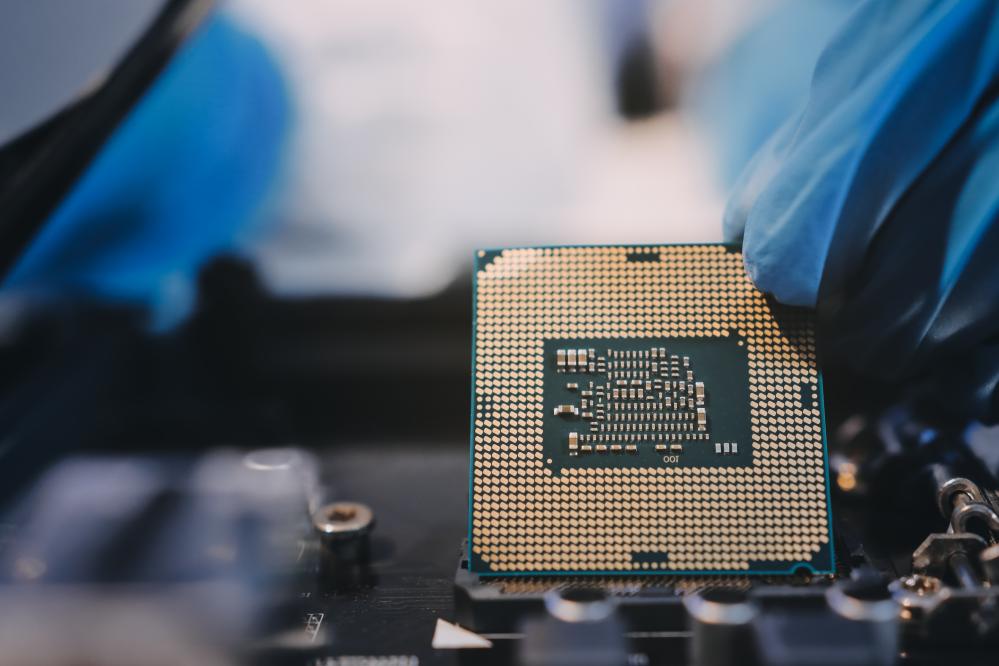

As a professional with over 20 years in the electronic component industry, I’ve seen supply chain disruptions significantly impact production. The semiconductor shortage has underscored the necessity for North Carolina to diversify its supply chain. This step is crucial for ensuring resilience against unforeseen disruptions, like natural disasters or global pandemics.

Focusing solely on one supplier can lead to bottlenecks. For North Carolina, exploring partnerships with varied suppliers will not only fortify the state’s position but may also generate new economic opportunities. Diversification is an often-discussed strategy that involves looking beyond established supply channels to find alternative paths and create a robust framework capable of withstanding unexpected challenges.

The Role of Emerging Technologies

With semiconductor production facing numerous obstacles, emerging technologies provide promising avenues for relief. Innovations in artificial intelligence and machine learning offer predictive analytics to anticipate shortages before they occur. This technology-driven foresight allows for proactive strategies in managing supply and demand.

Furthermore, advancements in materials science could contribute significantly. Innovative materials might serve as substitutes or improved versions of current semiconductor components, potentially reducing dependency on traditional supply sources.

- Enhanced predictive modeling

- Advanced materials research

- AI-driven supply chain management

How Industry Collaborations Can Alleviate Shortages

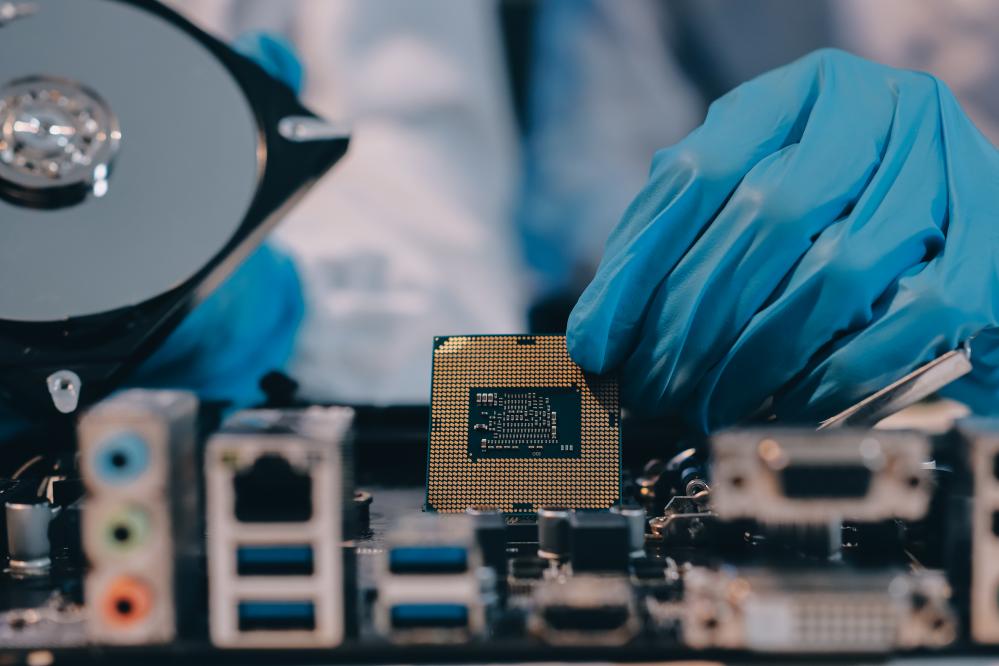

Collaborative efforts are key to addressing the semiconductor shortage in North Carolina. By fostering partnerships between research institutions, government entities, and private sector firms, strategies can be developed that support semiconductor resilience.

I’ve witnessed firsthand how partnerships can accelerate innovation. When industries come together, they can pool resources and expertise, thereby mitigating the risks associated with semiconductor shortages. These collaborations often spark technological advancements and establish best practices that benefit all stakeholders involved.

The state’s economic development initiatives should prioritize fostering such partnerships to build a semiconducture supply chain that is both sustainable and adaptable. These alliances can significantly reduce lead times and help navigate market fluctuations effectively.

What Lessons From Past Shortages Have Taught Us?

The lessons from past semiconductor shortages in North Carolina have highlighted the importance of readiness and adaptability. A quick response can make all the difference. Industries must embrace a culture that values innovation and quick adaptability. This involves learning from past mishaps and understanding the intricacies involved in supply chain dynamics.

1. Conduct a thorough analysis of previous shortages to identify patterns and anticipate potential future disruptions.

2. Develop contingency plans that incorporate flexible manufacturing processes and logistics alternatives.

3. Invest in workforce development to ensure that the skillsets required for advanced semiconductor manufacturing remain readily available.

How Can North Carolina Prepare for Future Shortages?

Preparing for future semiconductor shortages requires a multi-faceted approach. At the forefront is investment in research and development. North Carolina should aim to be a pioneer in semiconductor innovation. This means funding initiatives that push the boundaries of what’s possible in chip design and manufacturing.

Prioritize R&D: Increasing funding for semiconductor research initiatives will help prepare the state for the next generation of chip technology.

Workforce Training: Ensuring that the North Carolina workforce is equipped with the necessary skills for the evolving job market is crucial.

Financial Incentives: Offering tax breaks and financial incentives to semiconductor firms could attract more operations to the state, thereby strengthening the local industry.

Why is supply chain diversification crucial for resolving semiconductor shortages in North Carolina?

Supply chain diversification is a key strategy for building resilience against disruptions. Imagine relying solely on one route to get to work every day. If there’s a roadblock, your whole day is thrown off. This is similar to relying on a single supplier for semiconductors. By diversifying, North Carolina can create multiple pathways, reducing risks associated with natural disasters or global events. This approach not only strengthens the supply chain but also opens up avenues for innovation and economic opportunities. It’s like having multiple gears on a bike; when one fails, others are ready to keep you moving forward.

How can emerging technologies help alleviate the semiconductor shortage?

Emerging technologies, particularly AI and machine learning, are game-changers for predicting and managing semiconductor supply chains. Imagine having a weather app that not only tells you if it might rain but gives you a detailed week-long forecast. Similarly, AI enhances predictive modeling to foresee shortages before they hit, allowing companies to plan better. Advances in materials science also promise new alternatives to traditional semiconductors, reducing dependency on specific resources. Think of it as finding a new shortcut in your daily commute that not only saves time but is more scenic too.

What role do industry collaborations play in mitigating semiconductor shortages in North Carolina?

Collaborations across industries are pivotal. They’re like a symphony, where different musicians (or stakeholders) come together to create harmony. By pooling resources, expertise, and innovations, research institutions, government bodies, and private enterprises can tackle semiconductor shortages more effectively. In practice, this can lead to reduced lead times and shared best practices, fortifying North Carolina’s standing in the semiconductor industry. It’s akin to a neighborhood potluck, where everyone brings a dish, resulting in a feast larger than the sum of its parts.

What have past semiconductor shortages taught us about preparation and response?

Past shortages have underscored the need for readiness and adaptability. Consider it like a coach preparing a team for every possible scenario – the key is to stay nimble and informed. Analyzing past disruptions helps identify patterns and anticipate future risks. By building contingency plans and investing in workforce development, industries can remain agile and prepared. Think about it as upgrading both your computer’s antivirus software and your own skills to tackle new challenges and threats as they arise. What lessons from past disruptions can you apply to your own strategies?

How can North Carolina prepare for future semiconductor shortages?

To tackle future shortages, North Carolina must adopt a comprehensive approach that includes investing in R&D, offering financial incentives, and ensuring workforce readiness. Imagine preparing a garden by choosing the right seeds, improving soil quality, and keeping pests at bay. Similarly, by funding cutting-edge research and offering tax breaks, North Carolina can attract semiconductor firms and bolster local industry. Equipping workers with modern skills ensures the state is ready for technological advancements. Ultimately, it’s about creating an ecosystem that supports growth and resilience. How might these strategies impact your local community or business sector?

Resources

- National Institute of Standards and Technology (NIST) – Official website of NIST providing standards, measurements, and testing for various industries.

- National Centers for Environmental Information (NCEI) – Official website of NCEI offering climate, weather, and environmental data.

- North Carolina Department of Public Safety – Official website of the North Carolina DPS providing public safety information and resources.

- University of North Carolina System – Official website of the UNC System offering education and research resources.