The Landscape of Electronic Components in Massachusetts

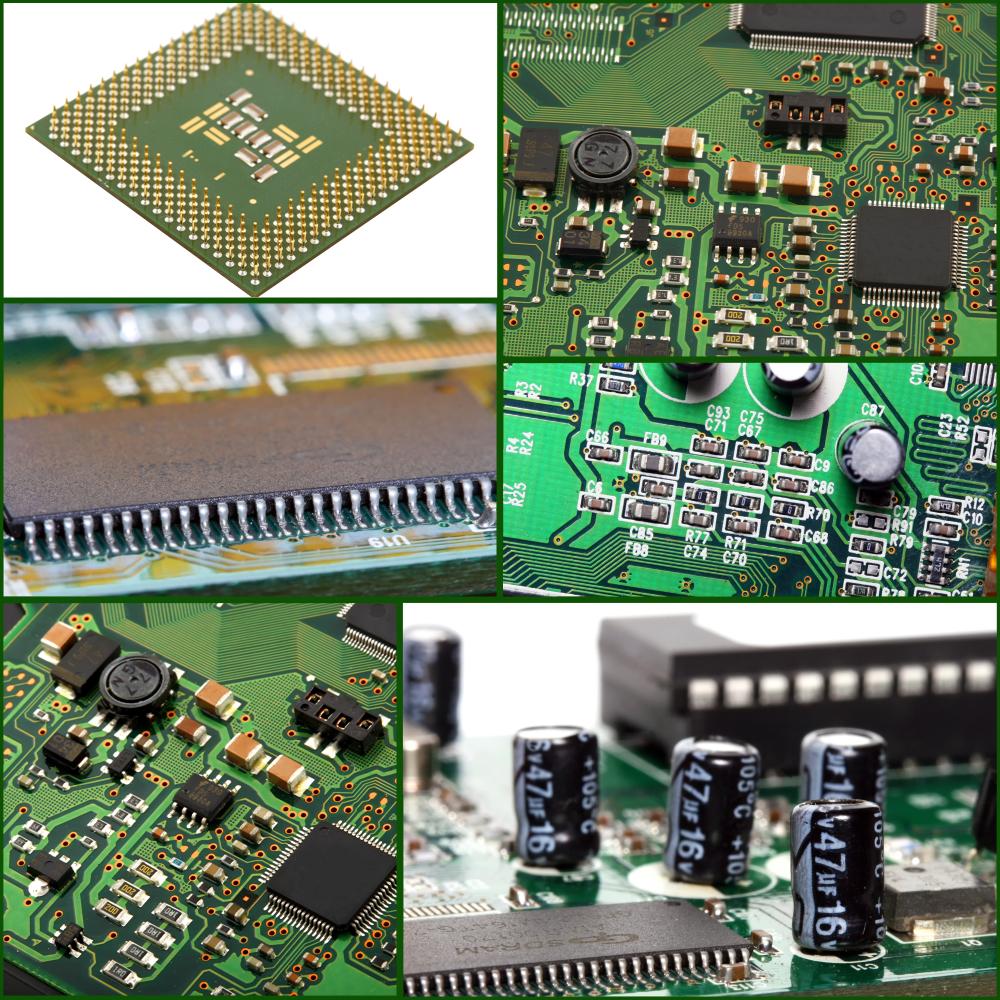

The state of Massachusetts, known for its rich history and vibrant innovation ecosystem, plays a significant role in the landscape of electronic components in the United States. From the bustling streets of Boston to the industrial hubs of Framingham, the demand for electronic components spans a wide array of sectors, including aerospace, defense, medical, and consumer electronics. The keyword phrase Electronic Components Massachusetts embodies a marketplace teeming with potential and innovation. With a history of technological advancement, Massachusetts attracts startups and established firms alike, all seeking to tap into this dynamic sector. Entrepreneurs and engineers in the region often discuss the unique advantages and challenges faced by businesses dealing with electronic components in Massachusetts.

For over two decades, I have had the privilege of working in this vibrant marketplace, witnessing firsthand the rapid evolution of technologies and the shifts in supply chain dynamics. Companies like Synergy Components, with their extensive global network, provide essential services such as material supply chain solutions and reliability testing to ensure that businesses can operate efficiently and effectively.

Innovations in Electronic Component Supply Chains

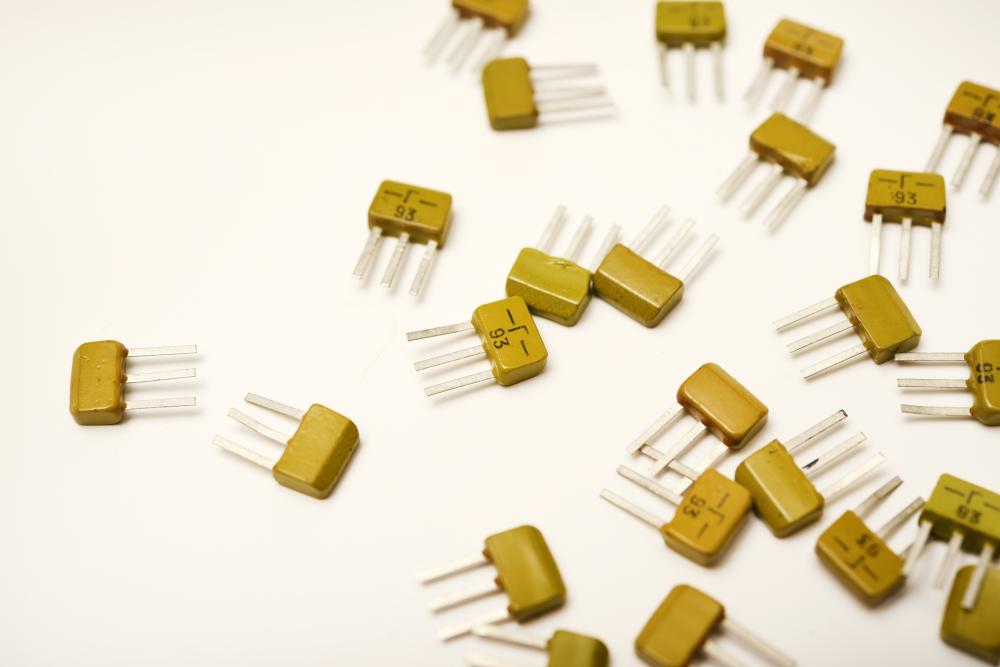

Supply chain management for electronic components is a critical area where Massachusetts has excelled. With the rapid pace of technological change, companies must stay ahead by continuously improving their supply chain processes. Synergy Components, for example, utilizes advanced logistics and reliable testing methodologies to tackle the challenge of counterfeit components. This is crucial in maintaining trust and reliability in sectors where component failure is not an option, such as aerospace and medical industries.

One notable advancement in this domain is the implementation of real-time tracking systems that allow for precise monitoring of inventory levels, ensuring that businesses can quickly adapt to market demands. This level of adaptability is crucial for companies aiming to stay competitive in Massachusetts’ fast-paced electronics market.

My interactions with industry peers reveal that the emphasis on quality assurance and counterfeit mitigation is no longer a luxury but a necessity. Businesses require robust systems to prevent supply chain disruptions and protect their brand integrity. The collaborative environment in Massachusetts fosters innovation and drives collective efforts toward achieving greater efficiencies and reliability.

How to Improve Efficiency in Electronic Component Procurement

Improving efficiency in procuring electronic components requires strategic planning and execution. Based on my two decades of experience in this industry, here are some steps companies can take:

- Analyze Demand Predictively: Use data analytics to forecast future component needs based on historical trends and current market conditions.

- Develop Strong Relationships: Establish and maintain relationships with trusted suppliers to ensure priority service and better negotiation terms.

- Implement Quality Controls: Use strict quality control measures to detect and prevent counterfeit parts, ensuring product integrity.

- Leverage Technology: Invest in supply chain management software that provides real-time analytics and inventory management capabilities.

By taking these steps, businesses in Massachusetts can streamline their procurement processes, reduce lead times, and ultimately improve their bottom line.

Unique Solutions for Component Design Challenges

The challenge of designing electronic components that meet specific client needs is one that many Massachusetts companies face. This challenge becomes even more pronounced when dealing with legacy systems or when innovation is pressed by strict budgets. It is here that creativity and engineering expertise shine. Companies like those we work with have developed a strong reputation for providing customized solutions that cater to unique requirements, whether developing new product designs or adapting existing solutions for emerging applications.

In my experience, collaboration between design teams and clients has been a game-changer. By working closely with clients to truly understand their challenges and goals, Massachusetts firms can deliver solutions that not just meet specifications but also surprise and delight their customers. The integration of cross-disciplinary teams, blending expertise in engineering, design, and supply chain management, has proved to be a successful approach in overcoming design challenges.

Future Trends: What to Expect in Massachusetts’ Electronic Component Sector?

Looking ahead, several exciting trends are emerging within the Massachusetts electronic component sector. One such trend is the integration of sustainable practices within the supply chain, reflecting a growing emphasis on environmental responsibility. This aligns with broader industry shifts towards reducing carbon footprints and enhancing sustainability across all phases of the product lifecycle.

Another key trend is the increasing role of artificial intelligence and machine learning in optimizing component design and supply chain management. These technologies offer incredible potential for predictive analytics, enabling businesses to anticipate market needs with greater accuracy and agility. Furthermore, the rise of IoT and smart technologies continues to transform the landscape, creating new avenues for innovation and application.

As firms in Massachusetts continue to adapt and evolve, they must also remain vigilant to global supply chain disruptions that could impact the availability of critical components. Companies need to be proactive and flexible in their strategies, ensuring that they can navigate the complexities of the modern supply chain landscape.

In conclusion, Electronic Components Massachusetts is a dynamic field with numerous opportunities for growth and innovation. By understanding and leveraging the unique strengths of the Massachusetts marketplace, businesses can position themselves for success in this ever-evolving sector.

What makes Massachusetts a significant player in the electronic components industry?

Massachusetts is a hub of technological innovation and historical significance in the electronics industry. The state is home to a thriving ecosystem that includes both established firms and startups, especially in sectors like aerospace, defense, and healthcare. This combination of innovation and industry diversity creates a rich landscape for electronic components. At Synergy Components, we see Massachusetts as an essential node in our global supply chain, offering access to cutting-edge technologies and a diverse pool of talent. The collaborative environment in Massachusetts enables businesses to leverage cross-industry insights, driving innovation and growth. Have you ever collaborated with a Massachusetts-based firm, and if so, what was your experience like?

How does Synergy Components ensure the reliability of electronic components in its supply chain?

At Synergy Components, maintaining the reliability and integrity of electronic components is paramount. We employ rigorous counterfeit avoidance measures and reliability testing protocols to safeguard the components within our supply chain. This involves real-time tracking systems and advanced quality assurance processes. Our clients, such as aerospace and medical firms, depend on these components to perform flawlessly, where any failure could have critical consequences. By integrating these reliability measures, we not only protect our brand but also offer peace of mind to our clients. Reliability is a cornerstone of our service; how do you ensure quality in your own operations?

What are some innovative supply chain advancements currently being implemented in Massachusetts?

Massachusetts is at the forefront of supply chain innovations, especially for electronic components. One of the most notable advancements is the use of AI and machine learning to improve supply chain efficiency. These technologies enable predictive analytics, allowing firms to accurately forecast demand and optimize their inventory. At Synergy Components, we leverage such technologies to streamline our operations and adapt swiftly to market changes. This technological edge is crucial for maintaining competitiveness in a fast-evolving industry. How do you integrate technology into your supply chain management?

How can businesses in Massachusetts improve their electronic component procurement processes?

Improving procurement efficiency is vital for staying competitive, especially in changing markets like Massachusetts. Businesses can start by using data analytics to predict demand and establish robust relationships with suppliers for priority access and better terms. At Synergy Components, we advocate for investing in cutting-edge supply chain management software to gain real-time insights into inventory levels. This also involves implementing strict quality controls to ensure that only authentic components are procured. By taking such strategic steps, businesses can enhance their procurement process, reduce costs, and improve overall efficiency. What strategies do you use to optimize procurement in your business?

What role does collaboration play in addressing electronic component design challenges in Massachusetts?

Collaboration is key to overcoming design challenges in the electronic components sector, especially in Massachusetts. Working closely with clients allows us to understand their specific needs and design constraints fully. At Synergy Components, we believe that bringing together cross-disciplinary teams comprising engineers, designers, and supply chain experts can lead to innovative and customized solutions. This collaborative approach not only meets client specifications but often exceeds expectations, providing even more value. Have you considered collaborating with external experts to tackle complex design challenges?

What future trends should Massachusetts-based firms anticipate in the electronic component industry?

Looking ahead, firms in Massachusetts should prepare for several key trends. One major shift is towards more sustainable practices in the supply chain, reflecting a broader industry commitment to environmental responsibility. Additionally, the role of AI and IoT technologies will expand, transforming component design and management. At Synergy Components, we are embracing these advancements and integrating them into our strategic planning to remain at the forefront. The ever-changing global supply landscape also demands agility and proactive strategies to manage disruptions effectively. What trends do you predict will shape the future of your sector?

Resources

- Massachusetts Government Website – Official website of the Commonwealth of Massachusetts providing information on various sectors and industries in the state.

- Massachusetts Institute of Technology (MIT) – Renowned research university known for its contributions to technology and innovation.

- Harvard University – Ivy League institution with a strong emphasis on research and academic excellence.

Austin

TX

78734