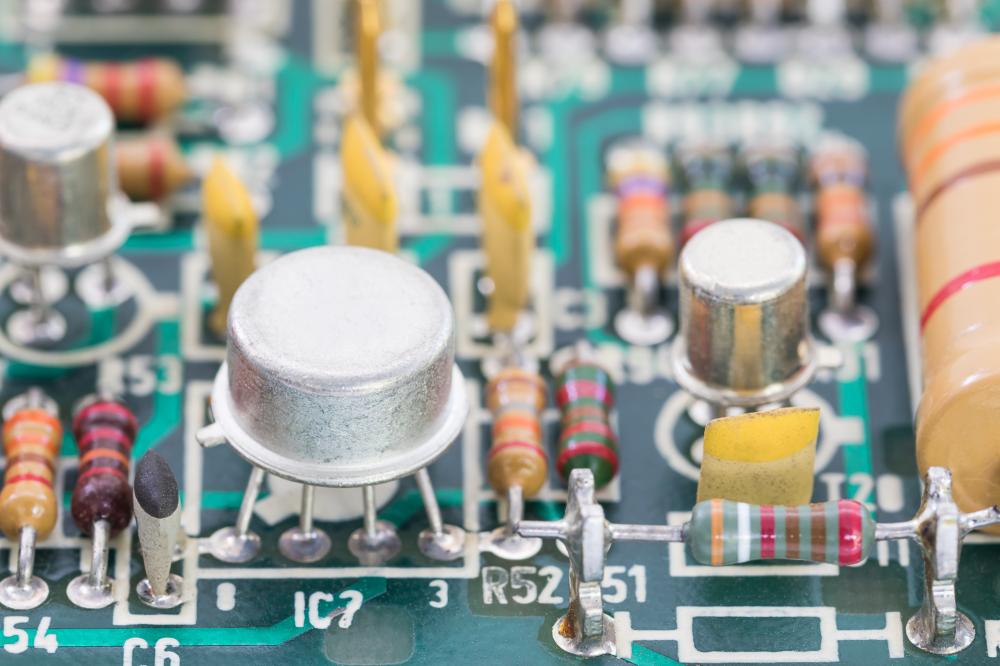

Navigating the Challenges of Hard-To-Find Electronic Components in North Carolina

As a seasoned professional with over two decades of experience at Synergy Components, the challenges associated with sourcing hard-to-find electronic components in North Carolina are all too familiar. The demand for precise, reliable parts continues to grow, especially in industries like aerospace, medical devices, and telecommunications. However, the supply chain has experienced significant turbulence. Issues like global component shortages, evolving technology standards, and counterfeit risks make component sourcing a high-stakes endeavor.

In the bustling tech hubs of North Carolina, such as Raleigh and Charlotte, there’s a constant race against time to secure components critical for innovation. Fortunately, experienced professionals have developed strategies to mitigate these challenges, leveraging advanced forecasting techniques and maintaining close relationships with an expansive network of trusted suppliers. By doing so, companies are not just surviving but thriving amid supply chain disruptions.

Strategies for Locating Elusive Components

One effective approach is developing a resilient supply chain network. At Synergy Components, we’ve established connections with over 5,000 manufacturers and distributors worldwide. This extensive network increases our chances of finding even the most elusive components. We prioritize long-term relationships with reliable partners who consistently deliver quality parts.

Another strategy is investing in technology. Advanced data analytics tools help us predict demand shifts and identify potential shortages before they happen. This proactive approach is essential in overcoming unexpected supply constraints, ensuring our clients in North Carolina remain competitive in their respective fields.

For those unacquainted with the component supply world, a simple step-by-step process can guide you to success:

- Identify the specific components that are hard to find.

- Leverage data analytics to forecast demand.

- Survey your network for potential suppliers.

- Validate the quality and authenticity of the components.

- Secure a reliable secondary source to safeguard against primary supplier failures.

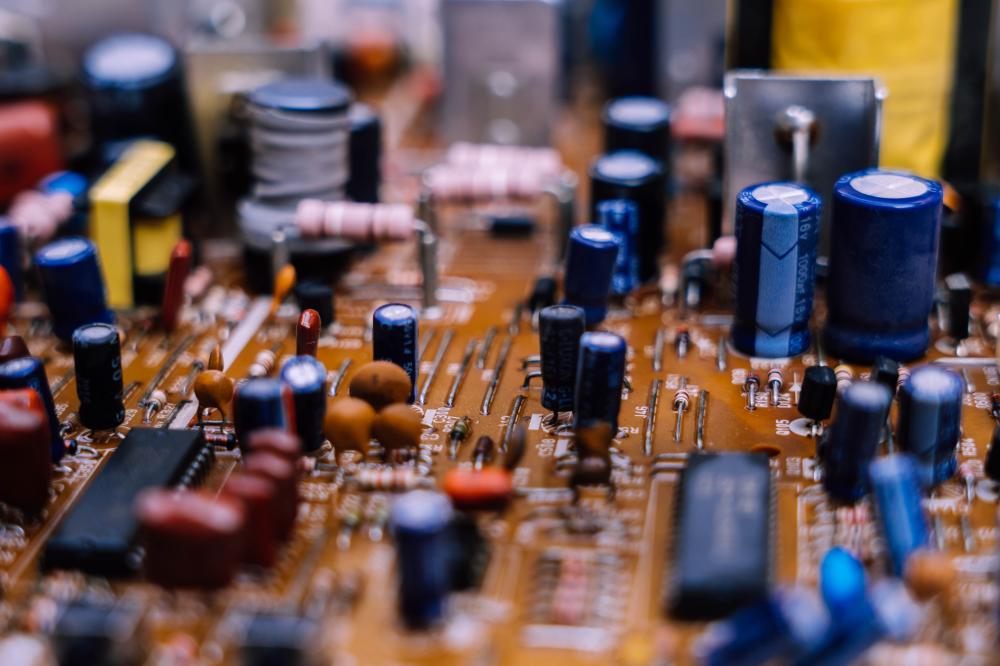

Adaptability in a Dynamic Market

The electronic components industry is anything but static. As I frequently remind clients, adaptability is your best ally. That’s why companies like ours are continually evolving. We employ stringent counterfeit avoidance protocols ensuring every component’s authenticity through rigorous testing.

Our adaptability also extends to offering customized solutions. At Synergy Components, customizing an obsolete part or creating a bespoke solution often becomes the linchpin of innovation, especially in North Carolina’s diverse industrial landscape. This not only saves on costs but also reduces lead time significantly.

Anecdotal evidence from clients speaks volumes about our approach’s efficacy. Ben M, a Director at a telecom giant, shared that our custom-made power supplies vastly reduced his team’s lead times, ultimately saving on overhead costs. This kind of adaptability is what sets a company apart in this volatile market.

What Qualifies as a Hard-To-Find Electronic Components North Carolina Emergency?

A hard-to-find electronic components North Carolina emergency is characterized by a sudden and critical need for specific components that are essential for maintaining production lines or completing pivotal projects on time. This urgent situation often arises due to unexpected supplier disruptions, delayed shipments, or catastrophic events.

When faced with such emergencies, the primary goal is to restore the supply chain as swiftly as possible. Companies must act quickly, leveraging emergency procurement strategies. Here, speed is of the essence. Access to a robust supplier network and a team skilled in rapid sourcing are invaluable assets.

Client Success Stories Speak Volumes

Our work with clients often becomes a testament to our strategies’ efficacy. Elise A, a Senior Buyer at a mid-size engineering firm in North Carolina, expressed her gratitude for how we helped recover assets on countless obsolete semiconductors. Our efforts prevented potential financial and operational setbacks.

Another noteworthy case involved Rin Y, a Commodity Manager at an international CEM. Following the Tōhoku earthquake and tsunami in 2011, Synergy Components provided vital support by sourcing necessary components amidst unprecedented supply chain disruptions. These real-world examples underscore the impact our expertise can have in crisis situations.

- Preventing counterfeit components

- Providing quick customizations

- Maintaining a seamless supply chain during global disruptions

These customer stories illustrate the tangible benefits of partnering with a seasoned components supplier, reinforcing the importance of experience and trust in the industry.

The Future of Component Sourcing in North Carolina

As technology evolves, so too does the landscape of electronic component sourcing. In North Carolina, staying ahead means embracing new trends and technologies. Innovations like blockchain for supply chain transparency and AI for predictive analytics are paving the way for more resilient supply chains.

Looking ahead, it’s crucial for companies to be proactive. While the past few years have been fraught with challenges, they have also been rich in opportunities to reimagine how we approach the sourcing of hard-to-find electronic components North Carolina needs. By integrating foresight with robust supply chain strategies, the future remains bright and full of potential.

What are the main challenges in sourcing hard-to-find electronic components in North Carolina?

Sourcing hard-to-find electronic components in North Carolina can be quite the adventure, given the supply chain issues that seem to crop up every other week. The main challenges usually revolve around global component shortages, rapidly changing technology standards, and the pesky counterfeit risks that can jeopardize entire projects. At Synergy Components, we’ve turned these stumbling blocks into stepping stones by leveraging our extensive network of over 5,000 manufacturers and distributors. It’s all about creating reliable connections that help us navigate these challenges and keep up with the demand for components in high-stakes industries like aerospace and telecommunications.

How does Synergy Components use technology to address these sourcing challenges?

We live in a tech-driven world, so why not use those smarts to fix our sourcing woes, right? At Synergy Components, we’ve embraced technology to predict demand shifts and spot potential shortages before they cause chaos. Through data analytics and advanced forecasting tools, we’re able to stay ahead of the curve. This proactive approach isn’t just for show; it significantly reduces the chances of unexpected supply constraints. And let’s be honest, having detailed data at our fingertips makes our jobs a lot easier and helps ensure our clients in North Carolina stay competitive.

What qualifies as a ‘hard-to-find electronic component emergency’ in North Carolina?

Picture this: You’re working on a major project, everything’s sailing smoothly and suddenly there’s an urgent need for a specific component. This could be due to unanticipated supplier disruptions or catastrophic events. That’s what we call a ‘hard-to-find electronic component emergency.’ In such situations, our primary goal at Synergy Components is to quickly restore the supply chain. We leverage our robust supplier network and rapid sourcing skills to tackle these emergencies head-on. The key here is speed, and having a seasoned team who knows where to look.

How does Synergy Components ensure the authenticity of components and avoid counterfeits?

Counterfeit components are like the unwelcome gatecrashers of any party. At Synergy Components, we’re firm believers in saying ‘not on our watch.’ To ensure authenticity, we employ stringent counterfeit avoidance protocols that include rigorous testing. Every component is screened with a meticulous eye to eliminate risks. Our commitment to quality is not just a tick-box exercise; it’s a cornerstone of our business. Plus, with industry-standard certifications like an ESD Certificate and ISO Certificate, we maintain credibility and trust with our partners and clients.

Can you share a success story of how Synergy Components handled a supply chain disruption?

Absolutely, I love a good success story! Following the Tōhoku earthquake and tsunami in 2011, many companies faced unprecedented supply chain disruptions. For Rin Y, a Commodity Manager at an international CEM, these events could have spelled disaster. But by partnering with Synergy Components, they managed to source necessary components and keep operations running smoothly. Our expert sourcing and reliable network turned a potential crisis into a testament to resilience and adaptability. This story just goes to show the impact that strong partnerships can have in even the toughest of times.

What strategies does Synergy Components use to locate elusive components?

Finding those elusive components can be like searching for a needle in a haystack. At Synergy Components, we start by building and maintaining a resilient supply chain network. By establishing strong connections with manufacturers and distributors globally, we enhance our chances of locating even the hard-to-find parts. We also invest heavily in technology, utilizing data analytics to predict demand shifts and stay ahead of potential shortages. This blend of network strength and technological foresight forms the backbone of our sourcing strategy.

How does adaptability play a role in the success of electronic component sourcing in North Carolina?

Adaptability is the secret sauce to success, especially in the dynamic world of electronic component sourcing. At Synergy Components, we pride ourselves on our ability to adapt to changing market conditions. This means employing stringent protocols to avoid counterfeits, offering customized solutions, and even altering obsolete parts to fit current needs. It’s all about staying flexible and open to new ways of doing things. One of our clients, Ben M., highlighted how our custom-made power supplies slashed lead times and overhead costs, proving that adaptability isn’t just a buzzword–it’s a game-changer!

What does the future of component sourcing look like in North Carolina, and how is Synergy Components preparing for it?

The future of component sourcing in North Carolina is as exciting as it is challenging. With advancements in technologies like blockchain for supply chain transparency and AI for predictive analytics, we’re entering a new era of sourcing efficiency. At Synergy Components, we’re gearing up for this future by proactively integrating these innovations into our processes. By doing so, we’re not just reacting to change; we’re leading it. This forward-thinking approach ensures that we continue to deliver top-notch solutions, keeping our clients ahead of the curve and ready for whatever the future holds.

Resources

- National Institute of Standards and Technology (NIST) – Official website of NIST providing resources on standards and technology.

- NC State College of Education – Homepage of NC State College of Education offering educational resources.

- North Carolina State Government – Official website of the North Carolina state government providing a wide range of resources.

- Institute of Scrap Recycling Industries (ISRI) – ISRI’s homepage offering resources on recycling and sustainability.

- Ohio State University Department of Electrical and Computer Engineering – Homepage of the ECE department at Ohio State University offering educational resources.